K-Bin

Welcome to K-Bin

For over 30 years, K-Bin has been a premier producer of high quality, high performance rigid compounds and pellets for the most demanding of blow molding, injection molding, extrusion applications and rigid processing applications. K-Bin employees strive for continued production excellence and continue working on sustainability and corporate social responsibility.

Why the name K-Bin?

K-Bin’s name is derived from founder Dr. Kanagawa. The K stands for Kanagawa and Bin means Box.

His dream, vision and goals came to fruition, as K-Bin now has two independent operating facilities and is a major part of Freeport operations.

We follow our parent company’s lead on CSR

- A unique team of knowledgeable people committed to customer service

- K-Bin uses Shintech PVC resin for high quality consistent compound

- Two independent plant sites for continuity of service

- Able to export anywhere in the world

- No customer too small or too large

- Backed by Shintech and Shin-Etsu

- Sustainability and Corporate Social Responsibility are significant characteristics of our culture

- Continual growth supports our customers’ growing needs

- K-Bin is familiar with NSF, ASTM, FDA, UL, Canadian Standards, PPI, Reach and RoHs requirements to name a few of the more frequently asked for standards.

Compound

- High Quality

- High Performance

- Rigid Vinyl Compounds

- Pellets

- Dryblended Powders

Products and Application

K-Bin manufactures a broad range of sophisticated Rigid Vinyl Compounds in the form of pellets and/or dry-blended powders including :

- Clear compounds for bottles, extruded rigid films or pipe

- Pigmented compounds for use in the manufacture of building products such as pipe, siding and window lineals, fence

- Pigmented and clear compounds for use in the manufacture of custom extruded profiles

- Superior foam compounds

- Injection molded compounds

K-Bin can ship in railcar, super-sacks or boxes.

Each compound can be adjusted for the customers tooling and equipment as well as market needs such as physical properties, color and gloss/ texture of the surface.

Compound Development

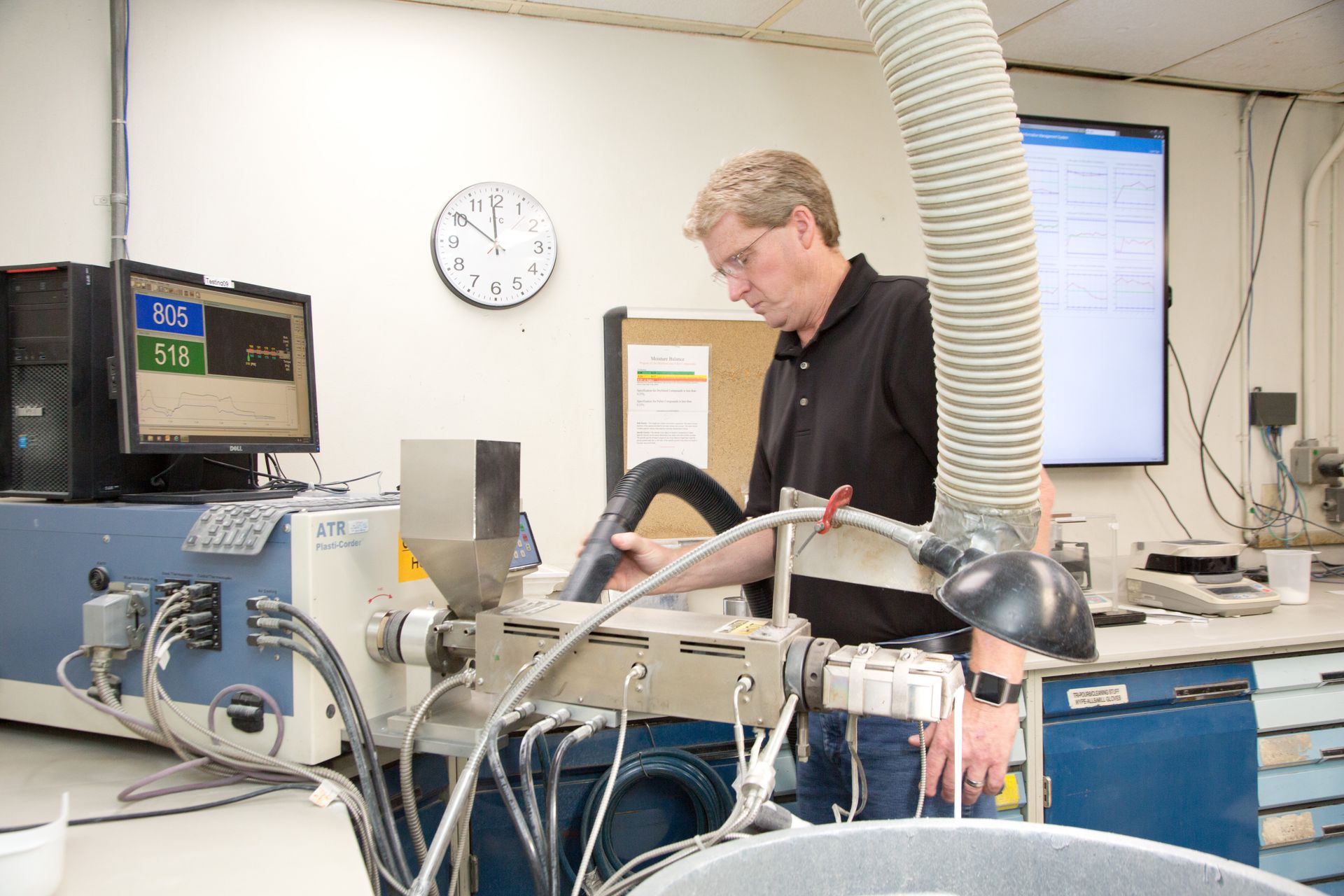

K-Bin maintains a state-of-the-art compound development and testing facility which includes:

- Physical property testing

- On-going outdoor weathering program

- Accelerated weathering testing

- Color analysis and development

- Analytical testing

- Production-size extruders, single and twin screw, utilizing commercial dies contributing to compound development and customer support

Specific compounds conform to many code and regulatory requirements, such as UL, NSF, AAMA, VSI, ASTM, NFRCA, ICC, etc.

Sales and Service

K-Bin’s Regional Sales Managers are well-trained professionals with direct access to and input in decision making.

Customer Order Service Network

that is highly responsive and provides constant access to production and shipping schedules.

Experienced Technical Team

provides support in the form of Field Engineering Service and/or Compound Development, as required.

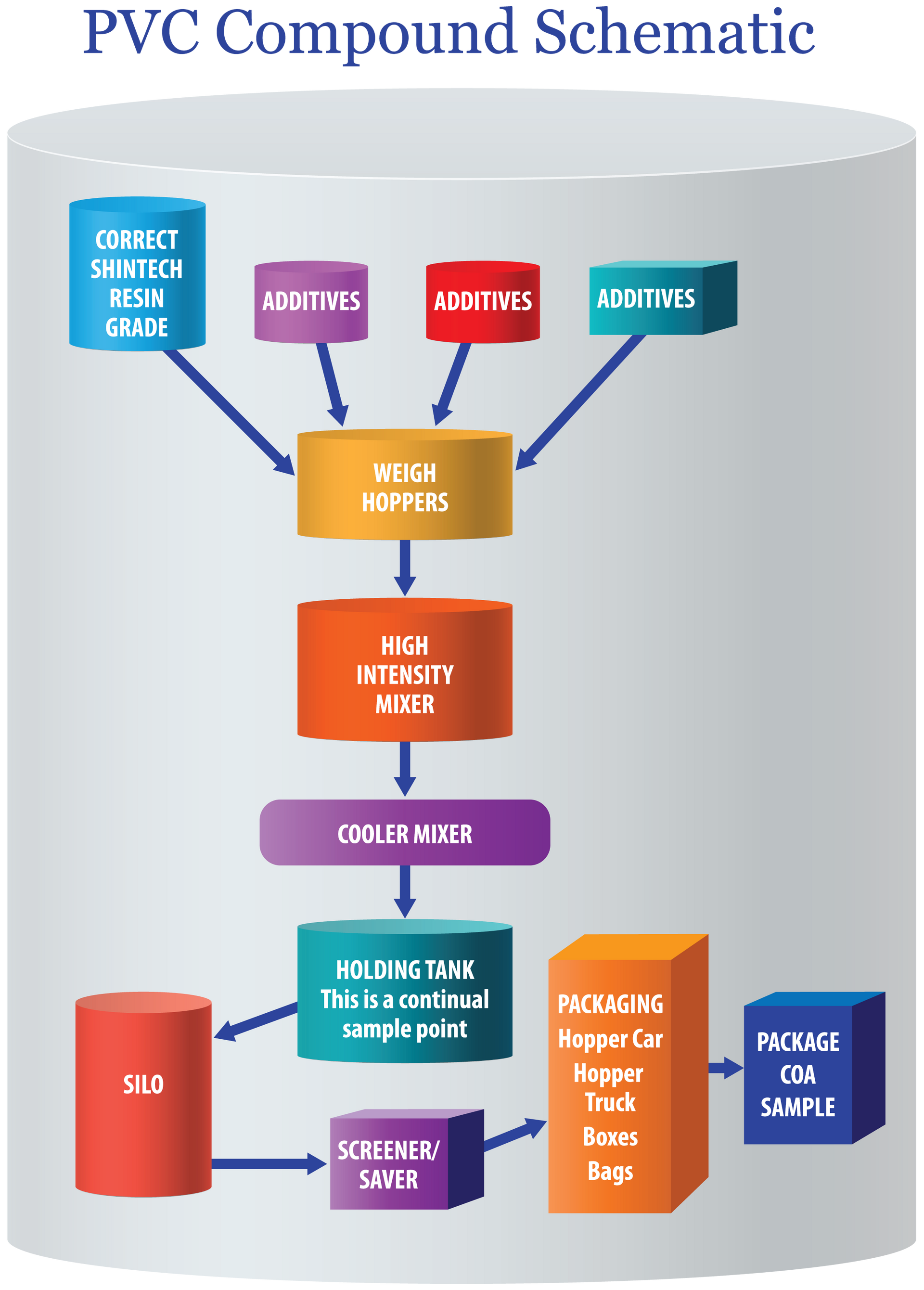

Manufacturing

- K-Bin’s manufacturing processes are highly automated providing the utmost in control and consistency from batch to batch

- Permanent record of every batch

- Programmed mixing cycles optimize efficiency and quality

- Automated sequence hold and batch diversion minimizes production of out-of-specification material and assures isolation

- Separate holding bins for each raw material minimizes the need for clean down and possibility of contamination

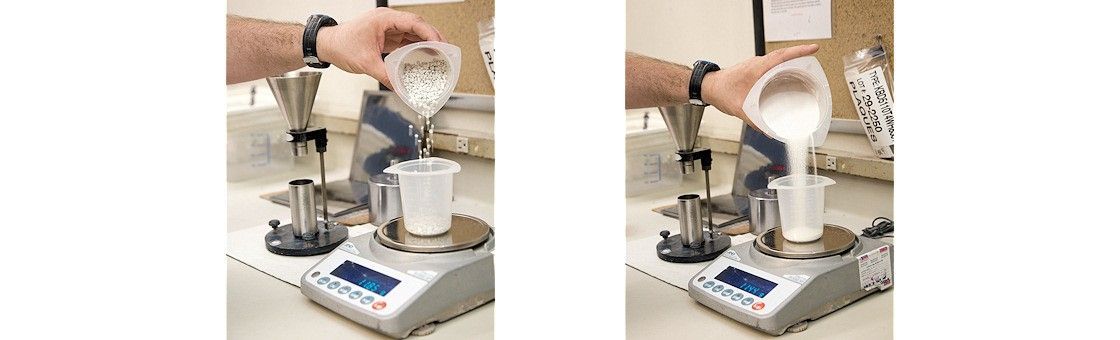

Quality Control

Effective lot traceability is provided through a number of procedures

- Raw material lots used on any individual batch can be identified

- Actual weights used in each batch are recorded

- Mixing conditions for each batch are recorded

- All ''alarms'' that occur in the mixing system are recorded

- 2015 ISO 9001 Certification for K-Bin

Quality Control Procedures include constant on-line inspection of product by plant operators and inspection of finished product for conformance to tight specifications.

The K-Bin Compounding Team is ready to help you with your compounding needs.

We want to help you grow and meet your market needs with the latest compounds and technology.

K-Bin conducts its operations in an environmentally responsible manner that is protective of the community.

K-Bin is committed to:

- Compliance with applicable legal regulations and with other requirements we subscribe to which relate to our environmental aspects.

- Prevention of pollution

- Minimization of waste

- Continual improvement of our environmental management systems.

- Setting and periodically reviewing environmental objectives and targets promotes excellence in environmental leadership.

K-Bin conducts regular safety and environmental inspections and audits to test site programs. Employees can also report any safety or environmental opportunity to their department supervision.